Now a day’s continuous exploration of coal to meet the demand for production and growth of manufacturing industries. In the current scenario, conveyor belts are vastly used for material handling in bulk amounts and transportation of coal inside and outside the facility.

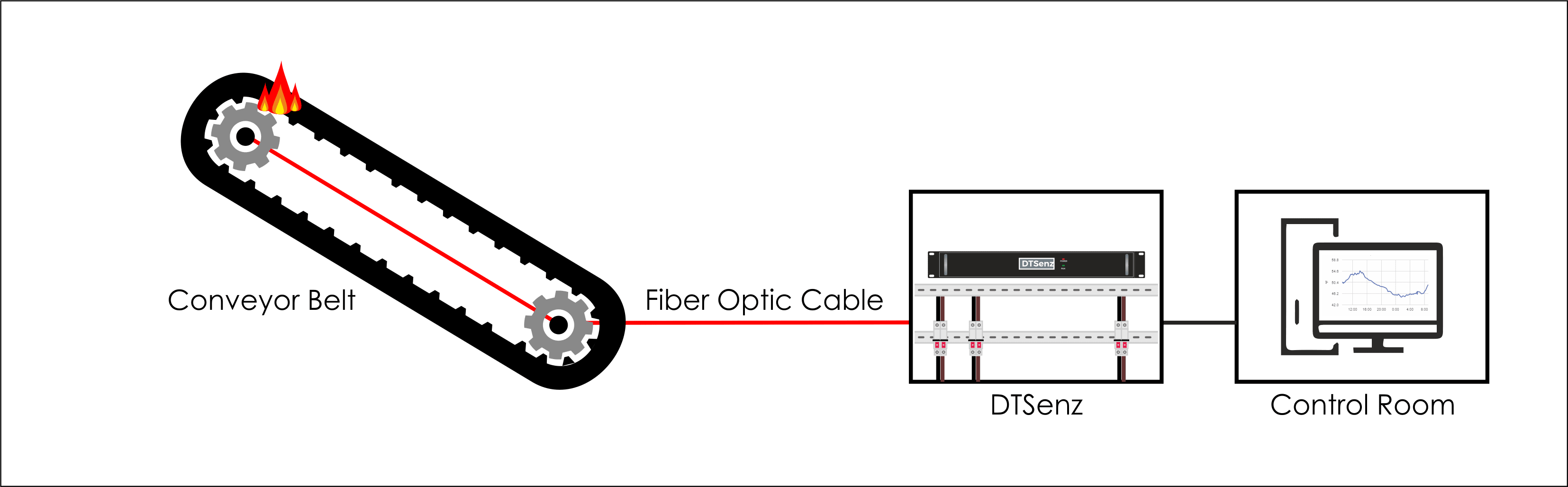

For mass handling of coal, conveyor belts are used. The most critical challenge is instant fire generated by any friction or heat transferred from moving parts to inflammable-coal carrying conveyor belts. These can cause loss of mining infrastructure and generate toxic fumes that affect human life.

The issue for mining companies is to detect any incident earlier to prevent any loss to assets or humans and take preventive action. It is a matter of higher interest to monitor heat generated around the surface of a conveyor belt by installing many sensors.

Fsenz is Organised and Managed by Tempsens Instruments (I) Pvt. Ltd. is one of the largest solution providers for Thermal and Cable Products. The manufacturing facilities are based in India, Germany, and Indonesia. It’s a part of Pyrotech Group, which was established by four technocrats in 1976 at Udaipur, Rajasthan with the first product as Thermocouple and RTD.