Overview

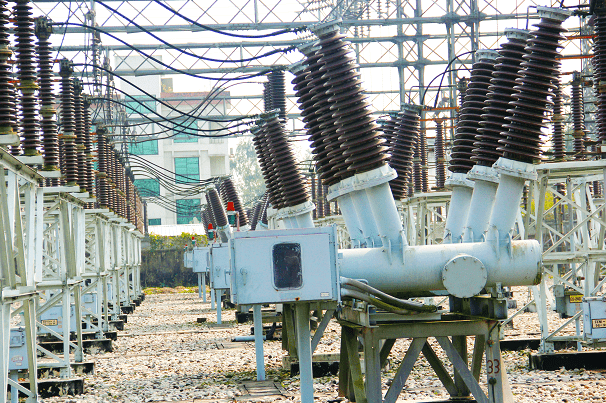

fSENZ’s offered fiber optic temperature sensing (FOTS) is ideal for monitoring the temperature of oil-filled transformers and cast resin transformers. Temperature sensors from fSENZ are completely immune to EMI/RFI and high-voltage environments, making them suitable for monitoring transformer winding hot spots. For power and distribution equipment, fSENZ has developed accurate, real-time smart grid temperature monitoring solutions for power and distribution equipment.

Our state of art solution to Transformer Industries

Fibre optic temperature sensors have been installed in high-voltage oil-filled transformers for over more than twenty years and are now considered the preferred method of transformer monitoring. The benefit that fibre optic sensors offer transmission and distribution (T&D) companies is monetarily important. By monitoring temperatures at each transformer winding hot spot, utilities are able to operate the transformer at peak capacity, without extending into overload conditions that increase the life of the transformer. This efficiency both in transmission throughput and service life can translate into savings of thousands of rupees annually, and make direct winding temperature sensing capability a must-have.

fSENZ’s low-cost fibre optic temperature sensing technology makes smart grid transformer temperature monitoring even more fascinating. For oil-filled transformers, fibre optic temperature probes are designed from high-dielectric strength materials such as Teflon and polyimide coated silica fibre so that they can withstand long-term dipping in transformer oil and kerosene desorption during manufacturing. A special tank wall feed-through is used to transmit the fibre sensor signal from the fSENZ’s optical temperature transmitter to the probe installed directly at the transformer winding hot spot locations.

Customer Benefits

- fSENZ’s fibre optic temperature transmitters are mounted in an external control cabinet with the temperature outputs fed into real-time monitoring and control software.

- With fSENZ’s optical temperature sensors installed, operators can monitor load conditions in real-time, reducing waste energy production and reducing the environmental burden.