Overview

The cost-effective fiber optic temperature sensors from fSENZ monitors switchgear temperature in real time at critical contact points to quickly detect overload and fault conditions. The complete solution from fSENZ includes both analogue output and RS-485 Modbus communication for easy integration with existing PLCs and host monitoring software. Fiber optic temperature sensors from fSENZ provide precise sensing for safe and efficient switchgear operation.

Our state of art solution to Switchgear Industries

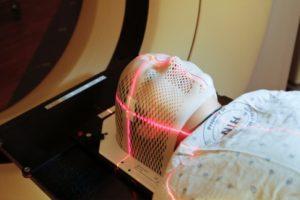

Fiber optic sensors are being used by utility companies all over the world to monitor the temperature of critical medium and high-voltage switchgear in the smart grid. Our sensors enable operators to maximise load efficiency and balance thermal stresses that can lead to catastrophic failures by providing real-time temperature data logging via USB. If left unchecked, even minor resistance increases can quickly spiral out of control, as higher resistance leads to hotter conductors, which leads to higher resistance. To optimise maintenance schedules and extend equipment lifetime, transmission and distribution (T&D) companies routinely specify the requirement for continuous switchgear temperature monitoring.

However, finding a cost-effective technology for high-voltage sensing applications has been one of the challenges. Various wireless RF (radio frequency) and IR (infrared) thermometer sensors have been used, but each has flaws. The inherent noise and interference that exists in a high-voltage environment can cause RF transmitter/receiver sensors to lose signal or show temperature spikes during switching operations, resulting in false alarms. Due to the use of electronic components, the temperature range of these sensors is typically limited to below 120°C for long-term use. Remote infrared temperature sensors have a similar fate because they require shielded electrical wiring and special mounting points that are precisely aligned with the object surface to be sensed. Dust accumulation and emissivity changes caused by subtle surface corrosion are known to cause temperature shifts in infrared thermometers, especially on shiny metallic surfaces like copper bus bars. Reflected infrared energy emitted by surrounding objects can skew the reported temperature, and sudden changes in ambient temperatures can also introduce measurement error.

Customer Benefits

- The technical challenges associated with conventional temperature sensors are not present with fSENZ’s fiber optic temperature sensors.

- Fiber optics temperature sensors are completely immune to electromagnetic interference and noise bursts caused by high-voltage switching and can be routed directly to critical switchgear monitoring points to detect hot-spot locations.

- Optical sensor cables are durable, can be made to custom lengths, and work in the same way as a traditional thermocouple.

- The fiber optic temperature probes from fSENZ are ideal for monitoring the temperature of smart grid switchgear.